Description

System is installed in more than 100 facilities around the world and is successfully used in descaling (rolling) operations.

After SCALEMASTER AP®, the new type SCALEMASTER AP® has been put on the market with its superior features.

SCALEMASTER AP® will provide you with a much better surface quality for better descaling and post thanks to our new type model with increased spray pulse density.

This newly designed SCALEMASTER AP® will provide high pressure and maximum effect with minimum energy.

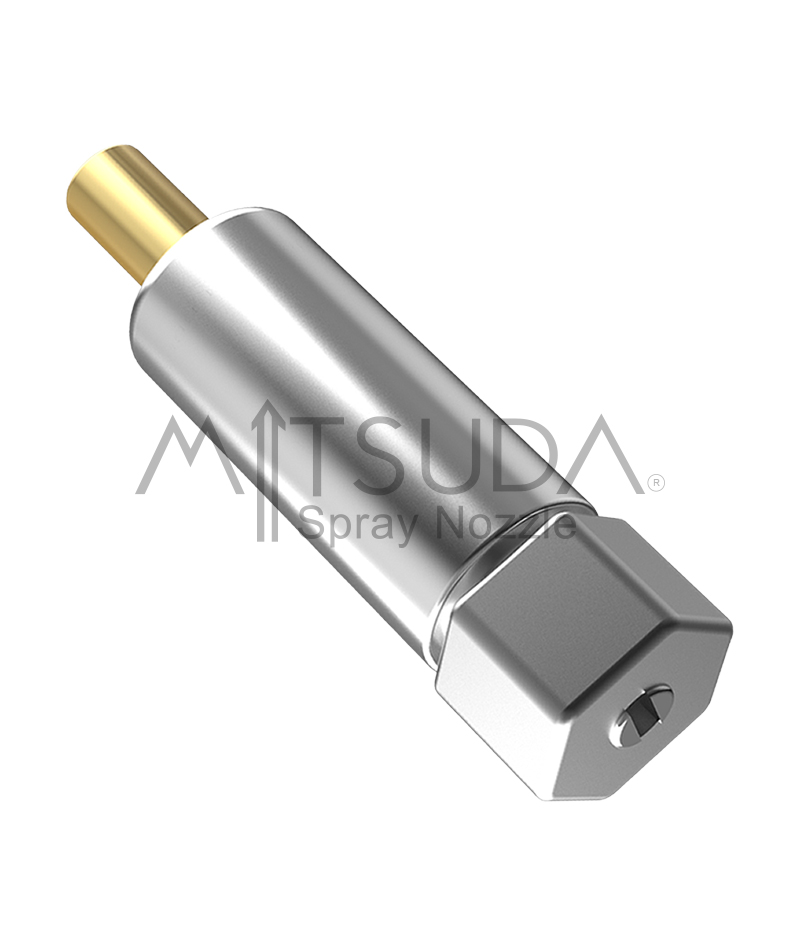

SCALEMASTER AP® nozzle tips are manufactured with the highest technology and designed to have an excellent effect sharper than a razor blade.

The most important points in the development of the new SCALEMASTER AP® are listed below:

- To ensure that nozzles have an equal effect on target surfaces

- Perfectly adjusting spray angles

- Keeping spray thickness at optimum level

- Adjusting the flow rates in the best way.

SCALEMASTER AP® nozzle tips are manufactured with the highest technology and designed to have an excellent effect sharper than a razor blade.

The most important points in the development of the new SCALEMASTER AP® are listed below:

- To ensure that nozzles have an equal effect on target surfaces

- Perfectly adjusting spray angles

- Keeping spray thickness at optimum level

- Adjusting the flow rates in the best way.

SCALEMASTER AP® can be produced and developed in the best tolerances according to the working conditions of your business.

Mitsuda is one of the few manufacturers in the world that can make the most advanced computer data based 3D and 5D modeling in-house, closely following the developments in the world and producing spray nozzles according to these results.

Many rolling mills around the world have benefited from the modeling developed by us, reducing the production cost and increasing the quality.

Old types of all SCALEMASTER AP® model tips are interchangeable with new ones.

Improved nozzle geometries within the orifice and flow zone reduce wear and improve jet quality.

As a result of greater demands on product surface quality and plant efficiency, descaling systems must operate more effectively and economically than in the past.

The key to improving a descaling process is directly proportional to the quality of the spray nozzles.

Improvements in nozzle and spray designs should focus on:

- Improving product quality

- To reduce the operating cost

- Reducing the energy consumption of pumps

- Late cooling of the product thanks to the leading sprays

Reviews

There are no reviews yet.